National Electrical Code (NEC) Section 300.21 deals with firestopping of electrical installations in fire-rated assemblies. This section is almost verbatim in Section 770.26 for optical fiber cables and Section 800.26 for communication systems. NEC Section 760.3(A) for fire alarm system refers you back to Section 300.21, and broadband communications system in Section 840.26 refers you back to Sections 770.26 and 800.26. These sections are often overlooked because the sections themselves do not give you much guidance on how to achieve these requirements. In fact, the informational notes in these sections even state that assistance in complying with these sections can be found in building codes. Now that the IAEI and International Code Council (ICC) are potentially joining forces, I believe this is the perfect time to address this section in a little more detail. In order to fully understand the point of firestop systems, we need to start at the beginning of what a fire-rated assembly is and what exactly penetrations are.

Fire-Rated Assemblies

A fire-rated assembly could be a wall, floor, shaft, roof, or exterior wall. These building elements are then assigned a fire rating based on what it is being used for, such as an occupancy separation wall, corridor wall, incidental use wall, etc. An exterior wall or roof may be rated because the building’s type of construction requires it to be or the walls distance to a nearby property line. Let’s take a building that contains an assembly space and a business space.

International Building Code (IBC) Section 508.4 tells us we need a one-hour rated wall between an assembly occupancy and a business occupancy in a sprinkled building. This wall would need to be rated for 2 hours if the building is not sprinkled. Now, this is under the assumption this is being built as a separated use building. There are ways of building non-separated use buildings, but we won’t get into that here. When it comes to rated walls, there are different types: fire partitions, fire barriers, firewalls, and smoke barriers. They are also smoke partitions. Fire partitions and the least restrictive, carry either a .5 to 1 hour rated and must terminate at the roof or floor sheathing above or at a rated ceiling and are usually used for corridor construction.

A fire barrier must, with no exceptions, terminate at the roof sheathing or floor above. These are generally used for occupancy separation walls and shaft enclosures and carry a rating of anywhere between one and four hours. Firewalls, which is a commonly misused term, is the most restrictive wall type that is used for building separations to create “separate buildings” These walls allow the collapse of the building on one side of the wall while allowing the building on the other to stay standing. There was a change in the 2018 IBC in regard to firewalls that may have some impact on whether separate electrical services are allowed, but that may be needed to be addressed in a future article.

There are many other places in the IBC that require rated walls, such as medical gas rooms, large mechanical rooms, etc. So how will you know if you are dealing with a rated assembly? I was a commercial plans examiner for a local jurisdiction and can tell you all plans with an architect involved should come with a “code plan”. This sheet will identify all rated construction. If a professional designer is not involved in the project, the general contractor should know if it is a rated assembly or not. As electrical professionals, it is not our job to know where a rated assembly is needed. We just need to be aware if one is being constructed so that we can meet the requirements of NEC 300.21.

Fire-rated assemblies are important building safety elements that must be taken seriously as they are designed to achieve building codes requirements for life safety. When these assemblies are required per the building code, it is important for us to maintain the integrity of these assemblies, and by firestopping our penetrations, we will achieve this. Rated assemblies are tested to procedures set forth in ASTM E119 or UL 263. In other words, rated walls, ceilings, shafts, etc., are tested to withstand the hourly rated they are given. It is not simply adding layers of sheetrock on a wall to achieve a rating. The IBC does give some prescriptive methods and other means to show compliance in Sections 721 and 722, but for the purpose of this article, we will not get into that. Since these assemblies are tested as such and not with specific penetrations, we create a “weak” point in the assembly wherever there is a penetration. Just as a mechanical engineer will spec a fire/smoke damper in a rated wall, we also need to be aware of our requirements.

Penetrations

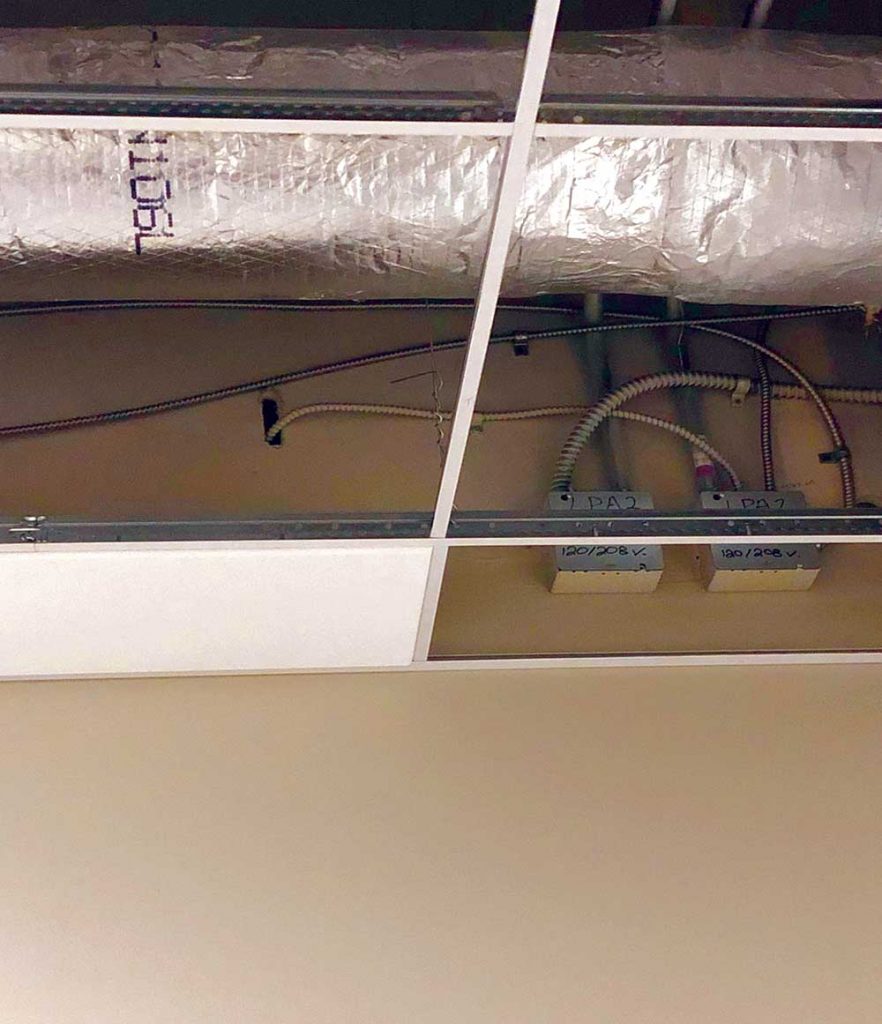

A penetration is a building element, plumbing, electrical, or mechanical system that penetrates a fire-rated assembly. There are two types of penetrations: membrane and through penetrations. These are all covered in IBC 714. A membrane penetration penetrates one side of the assembly (such as one layer of sheetrock on one side of a wall) while a through penetration goes all the way through the assembly. A lot of people think that just raceways and cables are penetrations, but electrical boxes, including panels, would be a membrane penetration as well if installed in a rated assembly.

So how do we achieve proper firestopping of our assembly penetrations? IBC 714 is where we need to go to find this information. It is an article I believe all electrical professionals should be aware of when installing electrical equipment. Once we are aware of a rated assembly, and we penetrate it with a raceway, cable, box, etc., we need to firestop it unless an exception is met. The firestopping method will be determined on what the penetrating item is and what the rating of the assembly is. Section 714.2 is important as it tells us that a listed penetration firestop system shall be installed with the manufacturer’s instructions. Section 714.4.1.1 states that, “through penetrations shall be protected using systems installed as tested in the approved fire-resistance-rated assembly.” What this means is that a through penetration system must be a tested system.

Hilti has a great website for searching for firestop systems. I would recommend this site for installers and designers looking for a specific system. When it comes to membrane penetration, Section 714.4.2 refers us back to Section 714.4.1, but there are many exceptions dealing with electrical penetrations. These exceptions detail how many square inches of the box are allowed within a ceiling area, listed box installations, steel conduit membrane penetrations, etc.

Shaft Enclosures

IBC 713 deals with shaft enclosures. Shaft enclosures are to be built as fire barriers in accordance with Section 707. Sometimes these are even referred to as a “building within a building” because of their strict requirements. Shaft enclosures are often used for elevator shaft construction and interior exit stairway construction. Since these have obvious life safety concerns, they are the most restrictive when it comes to penetrations. The most important section is 713.8.1, and it states, “penetrations other than those necessary for the purpose of the shaft shall not be permitted in shaft enclosures” In other words, unless that penetrating item is used for the shaft such as lighting, alarms, mechanical smoke control systems, etc. you cannot penetrate the shaft.

Many installers would love to use a four-story elevator shaft or interior exit stairway shaft to feed a rooftop unit, but this would be a violation. If you wanted to run a subpanel or branch circuit through the rated interior exit stairway to feed something on the other side, this would also be a violation. In fact, not even HVAC systems can communicate from the building into a shaft. There is an exception in Section 712 for two-story openings, so not EVERY elevator and every stairway are enclosed in a shaft. Once again, the code plan will inform you of where these shafts are located. Another important exception is in Section 713.8.1, where membrane penetrations are allowed on the outside of the shaft. You will see this for exit signs, receptacles, switches, etc., but again they must be on the outside membrane of the shaft enclosure.

Although this may be new information for someone unfamiliar with the building code, firestopping is an important element to maintain the integrity of fire-rated construction for life safety purposes. I highly recommend these sections listed to be read and understood by all electrical professionals. This information is all available on ICC’s website, so please take a look.

Find Us on Socials