The electrical industry and technology change every day to make our lives easier, faster, better, and all-around more fun. But with convenience comes a burden on us all to stay up to date with the ever-changing world. It’s our job not to get complacent and continue to grow with the times. Automation in our industry has created energy efficiency, smart technology, and major advances in electrical, fire & life safety systems.

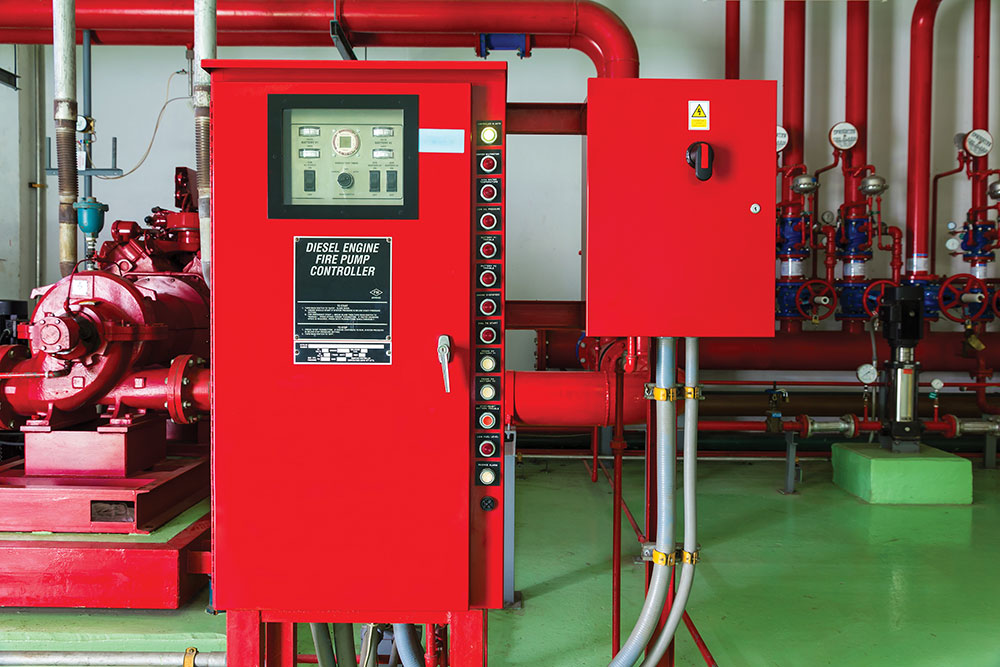

Simply put, the integrated fire protection and life safety system combines all the individual systems to create an overall building safety system. This system includes various systems that make up the fire protection and life safety system for a building that can include fire suppression, fire alarm and detection systems, security systems, HVAC, smoke evacuation and removal systems, elevators, emergency, standby systems, and even integrate assembly occupancy and special amusement ride evacuation processes. The integrated safety system tests all the inputs and outputs of the entire system to ensure it was installed and programmed as designed and operates as a single system.

For this article, I will focus my attention on the general requirements for NFPA 4, Standard for Integrated Fire Protection and Life Safety System Testing, and how it may become a part of your near future. I’ll be referencing the 2021 edition. The article will focus on the entire operating system and not any single integrated system. I’ve already seen this standard come into adoption in the local jurisdiction that I work in and change how the fire protection and life safety systems are commissioned, approved, and interact with each other to create an umbrella of assurance and safety for the occupants and the building itself.

The Scope, Purpose, and Application

NFPA 4 provides the minimum requirements for testing the end-to-end integration of fire protection and life safety systems. An end-to-end integrated system test is a test of the response of an input signal from the response of one or more individual systems to the output response of one or more integrated systems. The test and standard are required to prove that the sequence of operation or events between the relationship of fire and life safety systems function as designed and intended. An example would be that an initiating device sensed fire in a specific zone; the fire alarm system initiates the smoke control system and closes fire doors in that area to compartmentalize that zone and work towards removing the toxic smoke.

The standard applies to both new and existing integrated systems for life safety and fire protection. Note that NFPA 4 does not set the standard for testing individual systems that are the components of an integrated system. Those individual systems should be tested under their individual standard. The integrated testing should be performed where required by governing laws, codes, regulations, or the design documents and commissioning plan.

Origin and Development

Originally, the requirements for integrated safety systems came from chapter seven of NFPA 3, the Standard for Commissioning of Fire Protection and Life Safety Systems. The Technical Committee on Commissioning and Integrated Testing felt that there was a need to separate the requirements of commissioning fire protection and life safety systems and the integrated system testing into two separate documents. The Standards Council recognized the desire and approved the new project in October 2011.

The new project would focus on covering the testing of the performance of the interconnection between the fire protection and life safety systems. The new standard would also cover the development of the integrated testing team and the coordination between the testing agents and test team, the development of a test plan, testing scenarios for the specific system, and to spell out roles, responsibilities, and qualifications of all involved parties. In addition, the standard would provide protocols for the initial integrated testing that would take place before the Certificate of Occupancy being issued and address testing requirements for existing occupancies. And finally, the standard would address how the test plans were developed, testing scenarios, and the required documentation for the integrated safety system testing.

NFPA 4 and the Electrical Industry

What effect does NFPA 4 have on electrical inspectors, contractors, and designers? Our industry is directly involved with the individual systems that are integrated into the entire system. An example is a generator and the emergency and legally required systems that are backed up by it. These life safety systems are integrated with the backup power supply for the building. It’s common for electrical and fire alarm contractors to install parts, pieces, or the entire system that ties together the integrated systems. Electrical designers usually design the systems, the input, and the outputs of the matrix and develop the test plans. Building and fire departments, in general, are typically involved in the inspection, commissioning, and acceptance process, issuance of the Certificate of Occupancy, and the initial testing process.

The integrated system is a web of integration that ties together systems, devices, and equipment that provide a total package of fire protection and life safety. If a single element is impaired, it may impair the entire protection of the building occupants and occupancy. It’s not uncommon to have all the tradesmen involved present during these tests in case of a malfunction or issue. Their presence gives them an opportunity to correct the issue.

If you are involved in fire alarm, low-voltage, security, or emergency and standby systems, you may have a direct impact on how the integrated system functions as a whole and should have a basic understanding of the testing requirements. If this standard hasn’t been adopted in your local area, don’t be surprised if it is soon. Now’s the time to familiarize yourself with the integrated testing requirements and ensure that you are ahead of the adoption and prepared when and if it is adopted.

General Requirements

NFPA 4 is somewhat of a newer standard, releasing the first edition in 2015. Many states and local jurisdictions haven’t yet adopted it. If you are unfamiliar with the standard, don’t be surprised if it becomes a part of your near future. It is stated in Chapter 4, General Requirements, that the standard applies to both new and existing integrated systems. There are some variances outlined in Chapter 6, Test Frequencies, that outline specifically when existing systems need to be tested and have a testing plan created and what time that should happen within. The reason I mention that is because, again, it’s probably going to become a part of your near future if it hasn’t already. It’s best to familiarize yourself with the basic requirements and general knowledge.

Individuals involved in the integrated system testing are required to have some qualifications and requirements of NFPA 4. The qualifications must meet the requirements of laws, regulations, codes, and standards relevant to the individual systems. Those requirements must be available if requested by the authority having jurisdiction (AHJ). If there are no specific recognized qualifications for a specific integrated system, the testing agent should have skills and demonstrate the experience of the integrated operation of the system. Each agent should have the knowledge or experience of the design, installation, operation, and maintenance of the individual systems they are testing. The testing team should collectively understand how the entire integrated system functions, the installation and design, and the test plan designed with the system.

The owner’s responsibility is to ensure that fire protection and life safety systems integration testing is performed when required by laws, codes, and standards. If the owner chooses to delegate the responsibility to another person or organization, they are permitted to if they meet the requirements to do so. If the owner does decide to delegate the testing responsibilities to the integrated testing agent, a copy of the written delegation is to be submitted to the AHJ upon request. The integrated testing agent should plan, schedule, document, coordinate, and implement the integrated life safety and fire protection system. The integrated testing agent is also responsible for preparing and executing that test plan.

For new systems, the test plan needs to include at a minimum written verification the system has been installed per the design, a list of individual systems to be tested, required documentation, entities required to be present, equipment required to be tested, a comprehensive matric showing all inputs and outputs, the required testing frequency after the initial test, and the extent of the system testing needs to be identified. Existing systems follow similar requirements as new systems but need to be tested to ensure that the designs still conform to the original design. Buildings with limited integrated systems do not require a test plan, but integrated testing is still required.

Test Methods

One thing to note is that the standard does state that the risks associated with the integrated testing should be assessed during the test plan development stages. The testing cannot endanger the building occupants, personnel conducting the test, or the building contents and operations. The testing methods vary on the complexity and range of the system, but the entire system needs to be tested to ensure it complies with the specific design and all applicable codes and standards. The test scenarios may include events and a combination of events, including but not limited to loss of power, manual activation, water flow, and the presence of smoke. The combination of events during the testing may include simulated events to activate the system and should be documented. The test scenarios need to demonstrate that all the individual systems function as they were intended according to their specific code or standard to ensure the systems function per the design. The written documentation of the testing is to be provided to the building owner and stored at the premises. The documentation needs to show the completion of acceptance testing for each component system, verification of data transfer between the components, the test mode for each component, and the proper function of the integrated data-sharing system.

Test Frequency

The integrated safety system testing should take place upon the initial installation, periodically as the design intended to, and during a system modification that affects the integrated system. Keep in mind that an individual system modification that doesn’t affect the integrated systems doesn’t require an integrated systems test but the required test in accordance with the specific standard associated with the system. An example would be if a damaged fire door was replaced and the integrated system was not reprogrammed or modified, the door should be tested as an individual unit of the integrated system, but the entire system isn’t required to be retested. The test should verify the intended operation in accordance with either the commissioning plan or the integrated system testing plan.

New integrated fire protection and life safety systems must have periodic integrated systems testing as specified in the specific testing plan. Existing systems that are not limited integrated systems should have a test plan developed within five years of the adoption of the standard. Keep in mind that one thing referenced throughout the standard is to note when the standard is adopted. Some laws, regulations, and governing bodies do not require the standard yet. The new systems tested under this standard need to be retested every five years unless the specific testing plan permits a different frequency. The testing frequency and schedule for conducting tests should be completed and submitted for review, where governing laws, codes, standards, and regulations require it.

Integrated system testing may be required when an existing system is modified. Integrated systems should be tested when new fire protection and life safety systems are installed and integrated into an existing system; existing systems are modified to become an integrated system, or anytime there are changes made to the site-specific software. If an individual system part of an integrated system fails during testing, the affected integration functions should be retested to ensure their functionality. Where an individual system that is part of an integrated system is modified, the integrated systems affected by the change should be retested to verify the correct operation. Anytime changes are made to programming or integrated systems, there is a possibility for unknown changes or impairments. After changes are made, 10 percent up to a maximum of 50 devices should be retested to verify the correct operation of the integrated system.

Documentation

Some specific documentation requirements are outlined by NFPA 4 and reflect those required by other fire protection and life safety systems. Documentation is required for fire protection and life safety systems because those systems are required to be inspected, tested, and maintained throughout the lifespan of the building. The records are used to ensure that those processes follow the original intent of the design. One thing noted in NFPA 4 is that there are specific documentation requirements for the integrated system testing. The individual systems are still required to follow any other documentation requirements required by the approved installation standards referenced. The standard outlines the minimum requirements but does not prohibit additional records.

The final testing results need to summarize all the integrated test results. The test reports must include a narrative or matrix that identifies each response of not only the individual components but the integrated system too. Included also should be the status of each individual system for each test. The report needs to identify which tests were automated and where a device state change was initiated. A test report needs to be created and detail all the input and output functions that have been tested and operated correctly. Any deficiencies during the integrated test must also be recorded on that report.

The integrated testing agent is responsible for ensuring that all the reports are documented correctly, and all the records are accurate. The integrated testing agent should then turnover all the completed documents to the owner or any stakeholder that requests them. The property, building, or system owner or the owner’s designated representative is responsible for retaining the required documentation, and all the records need to be kept in one location. Those records need to be available if requested by the AHJ. Archiving the records is permitted if hard copies of the records are available upon request.

In Conclusion

The future of our industry is changing, and technology is driving many of those changes. Our part in the industry is to be open and receptive to changes, grow in our understanding, and never quench our thirst for learning. The complex fire and life safety systems increase the safety of people and stakeholders, and we need to be a part of that transition for a better tomorrow. The integrated fire protection and life safety systems are just another step in that process. It’s a standard that is not going away anytime soon and one that all electrical professionals should try to embrace. Just keep in mind NFPA 4 is just one piece of the puzzle of the entire picture. Just as individual systems are integrated into an entire system, building and fire codes mimic that umbrella. Many codes and standards play as a stakeholder to the entire purpose. To preserve and protect life and property. So, my suggestion is always once you familiarize yourself and learn one aspect, decide what you are moving to next.

Find Us on Socials