A significant change occurred in the 2008 National Electrical Code (NEC) at Section 250.32(B) pertaining to the acceptable grounding methods at buildings or structures supplied by a feeder or branch circuits from a grounded service located at another building or structure supplied from a common service. In this article, we will take a closer look at these changes and investigate the remaining options for these distinctive grounding methods. Some of the language and concepts discussed in this article are discussed in detail in chapter 13 of IAEI’s textbook, Soares Book on Grounding and Bonding, 10th edition.

Previous Requirements

Prior to NEC-2008, two general methods were recognized for grounding electrical systems at additional buildings or structures supplied from a common service.

Method 1. Equipment Grounding Conductor

In this method, an equipment grounding conductor was run with the feeder(s) or branch circuit(s), in addition to the ungrounded and grounded conductors to the additional building or structure. The installed grounded conductor would not be connected to the equipment grounding conductor or to the grounding electrode(s), which would be in violation of 250.24(A)(5) and 250.142(B). This method is similar, or identical, to installing a feeder to a panelboard or distribution equipment that is located in the same building or structure where the service is located. This method was described at 250.32(B)(1) prior toNEC-2008.

Method 2. Grounded Conductor

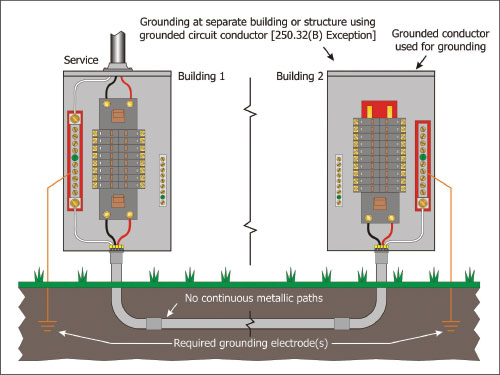

Section 250.32(B)(2) previously permitted the grounded circuit conductor (often a neutral conductor) to be grounded again and used for grounding purposes at the disconnecting means for the additional building or structure when the following conditions were met: (1) an equipment grounding conductor was not run with the supply to the building or structure, (2) there were no continuous metallic paths bonded to the grounding system in both buildings or structures involved, and (3) ground-fault protection of equipment was not installed on the common ac grounded service. By using this method, the grounded conductor was connected to the same terminal bar for the grounded conductors, the equipment grounding conductor(s), and the grounding electrode conductor(s) inside the additional building or structure disconnecting means enclosure.

Changes for 250.32(B)

Figure 1. Grounding at separate building or structure using the grounded (neutral) conductor is by exception for existing premises wiring systems only

For NEC-2008, the above-described method 2 was reduced to an exception that will apply to existing installations only (see figure 1).

There are instances where this method of grounding for existing separate building or structure is warranted and can be accomplished by compliance with this exception. However, for new installations, this revision requires installers to design installations of feeder(s) and branch circuit(s) to new additional buildings or structures that must include an equipment grounding conductor. This change further expands the NEC concept of migrating away from the use of the grounded circuit conductor for grounding past the first means of disconnect (load-side). An example of this migration was the changes to NEC-1996 at 250.60 [now 250.140 and 250.142(B)] for grounding of frames of ranges and clothes dryers.

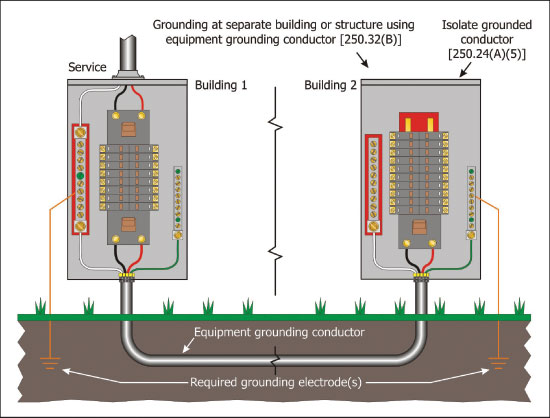

Figure 2. Grounding at separate building or structure using a required equipment grounding conductor for new installations

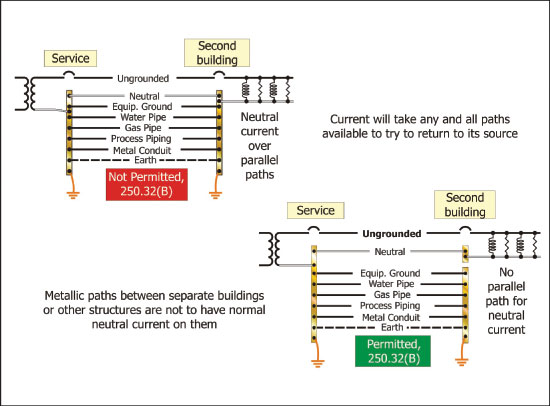

By changing the provisions of previous 250.32(B)(2) to an exception to 250.32(B), the NEC can continue to include requirements that would be applicable to existing buildings or structures grounded using the grounded conductor, while at the same time strengthening the requirement of 250.32(B) as the main rule prohibiting the use of the grounded conductor for grounding purposes for new installations. This change also helps reduce the number of designs that seemingly invite the possibilities of inappropriate neutral-to-ground connections that can and often do happen later, which is uncontrollable by any code rule.

As an example, while complying with previous 250.32(B)(2), there may not be a “continuous metallic path” between the two buildings or structures at the time of installation or the inspection by the authority having jurisdiction (AHJ). However, at a later date a phone line might be run between the two buildings or structures. How about a metal gas pipe? What about a low-voltage intercom system between the two buildings? However innocent these actions might be, they provide a “continuous metal path” between the two buildings that has the potential to introduce a parallel path for grounding that could result in a difference of voltage potential between these two paths.

Grounding with an Equipment Grounding Conductor

As described in method 1 of the previous NEC requirements, using the existing requirements of 250.32(B), an equipment grounding conductor is run with the feeder(s) or branch circuit(s), in addition to the ungrounded and grounded conductors to the building or structure. Any installed grounded conductor shall not be connected to the equipment grounding conductor or to the grounding electrode(s). The grounded conductors are isolated from the grounding terminations. This is often referred to in the field as a “floating” neutral system.

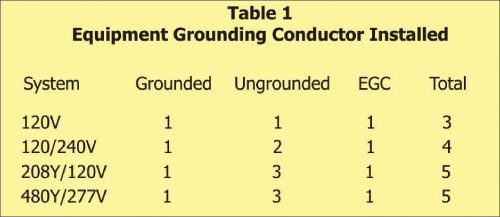

Table 1. Number of conductors with EGC installed

The equipment grounding conductor (which could be any of those specified in 250.118) that is run from the building or structure where the feeder or branch circuit(s) originates is connected to a terminal bar on the supply side of, or inside, the building or structure disconnecting means. This disconnecting means (or equipment) is grounded by connecting the required grounding electrode at the building or structure to the equipment grounding terminal bar of the disconnecting means enclosure. Equipment grounding conductors of the type included in 250.118 are acceptable and include conductors as well as some conduits or other raceways. The equipment grounding conductor (in a conductor form) that is run to the additional building or structure must be sized from Table 250.122 based on the rating of the overcurrent device protecting the feeder or branch circuit. The number of conductors for various systems that might be installed is summarized in a handy reference table included in this article (see table 1).

The grounded (often a neutral) conductor, installed as a part of the feeder or branch circuit from the building or structure where the service is located to the second or additional building or structure, must generally be an insulated conductor [see 310.2(A)]. The grounded (often a neutral) conductor(s) must be connected to the terminal bar for the grounded conductors, and the equipment grounding conductor(s) must be connected to the equipment grounding terminal bar where the grounding electrode(s) are connected inside the additional building or structure disconnecting means enclosure.

Grounding Electrode Required

Figure 3. Objectionable currents – paths

The general rule in 250.32(A) states that at each building or structure served by one or more feeders or branch circuits from a common service, a grounding electrode system or grounding electrode meeting the requirements of Article 250 Part III must be connected in a manner specified in 250.32(B) or (C). Where no grounding electrodes are present at the additional building or structure, a grounding electrode(s) required in Part III of Article 250 (specifically 250.50) must be installed and used. The grounding electrodes specified in 250.52(A) that must be installed and used at the additional building or structure as required in 250.32(A) include: (1) metal underground water piping, (2) metal frame of the building or structure, (3) a concrete-encased electrode, or (4) a ground ring. Where none of these electrode(s) are available at the additional building or structure, one or more of the following electrodes specified in 250.52(A)(4) through (A)(7) shall be installed and used: (5) a driven rod and pipe electrode, (6) other listed electrodes, (7) plate electrodes, or (8) other local metal underground systems or structures.

The following systems and materials are not permitted to be used as grounding electrodes at the additional building (or any building or structure) per the requirements of 250.52(B): (1) metal underground gas piping systems or (2) aluminum electrodes. Don’t confuse grounding and bonding requirements here. Metal underground gas piping is prohibited for use in a grounding electrode system but is required to be bonded to other metal piping systems and exposed structural steel for equal voltage potential purposes [250.104(B)]. The fine print note following 250.52(B) provides clear direction for the bonding requirements for any metal gas piping systems that are installed in or attached to the building or structure. A reference to 250.104(B) for the rules is provided.

The exception to 250.32(A) indicates that a grounding electrode at separate buildings or structures shall not be required where a single branch circuit supplies the building or structure and the single branch circuit, including a multiwire branch circuit includes an equipment grounding conductor for grounding the conductive non-current-carrying parts of all equipment. For the purposes of this section, a single branch circuit could be a multiwire branch circuit as indicated in the exception to 250.32(A).

Summary

Section 250.32(B) no longer permits the use of the grounded conductor, for grounding purposes at an additional building or structure fed by a feeder or branch circuit from a common service at any new installation. All feeders and branch circuits supplying new separate buildings or structures must include an equipment grounding conductor for grounding purposes. An exception to 250.32(B), which was previously a main body text rule at 250.32(B)(2), allows the use of the grounded conductor for grounding at the additional building or structure under specific conditions.

Find Us on Socials