Some states have been blessed with incredible natural resources. Florida has its orange groves while California has its fruits and nuts. Kansas has never-ending views of wheat fields for as far as the eye can see. South Dakota has some of the best pheasant hunting this country has to offer. Even Arkansas is known for locations where you can find diamonds, if you take time to look for them. And lest we forget about the rush to Alaska in hopes of striking it rich looking for gold. Upon moving to Texas several years ago it became apparent that one of the Texas natural occurrences (besides oil and cattle) was wind, and lots of it.

Wind has silently been responsible for helping to settle many parts of this great nation. As you drive through many of our midwestern states you will still see some majestic structures associated with wind power. Some are long since done accomplishing their work, while others are still working to provide needed water to the property they sit upon. Of course, I am speaking of the majestic windmills you remember seeing as you come upon farmhouses in the Midwest or cattle ranches in the southwest United States. Many of these windmills are being disassembled and sold to individuals wanting to own a piece of America’s great past.

But for many years there has been a growing recognition that wind could be much more useful than the localized windmill used for pulling water out of the ground. With the desire for alternative methods of production of electricity, wind has become a stable and never-ending source for electricity production.

But with new technologies comes the recognition that safety standards be in place to protect not only the equipment but also the workers servicing these wind electric production units. This article takes a look back and reviews the history of wind and its safe use in the role of producing electricity.

Birth of Wind Electric Systems into the NEC

The 2011 National Electric Code (NEC) was the first edition to see an article towards the installation of Wind Systems. This new article was entitled Small Wind Electric Systems and was located in Chapter 6 at Article 694. This article is under the purview of the National Fire Protection Association (NFPA) Code Making Panel-4. If you look closely you will see a pattern between the layout of this new article and that of Article 690 for Photovoltaic Systems and 692 for Fuel Cell Systems. Article 694 includes several parts which are listed below:

- Part I- General

- Part II- Circuit Requirements

- Part III- Disconnecting Means

- Part IV- Wiring Methods

- Part V- Grounding

- Part VI- Marking

- Part VII- Connection to Other Sources

- Part VII- Storage Batteries

- Part IX- Systems Over 600 Volts

The installations of hundreds of small wind turbines initiated the necessity for this new article as many installers and inspectors were finding difficulties installing and inspecting these systems. It was felt that the electrical safety of these installations could be greatly improved if the information was included within the NEC.

For the 2014 NEC, a few noticeable changes took place for Article 694. In the title of the article, the word “Small” was removed. The reasoning behind this was that in many cases there is nothing “small” about the size of a wind turbine installation. (See Photo 1)

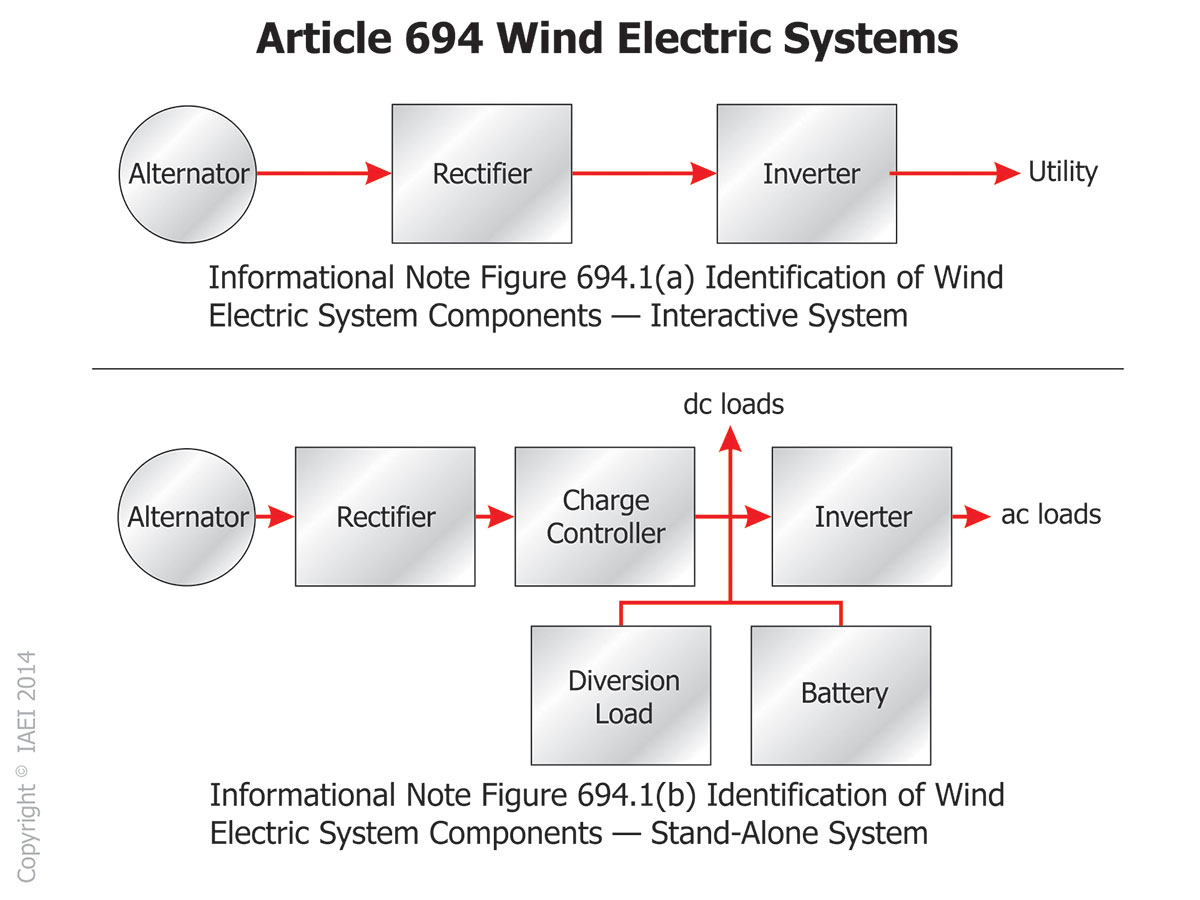

Proposals were submitted toward another change in the text as there was no significant difference between an electrical installation for a wind turbine sized at 100 kW or less and that for one rated above 100 kW. The requirements developed for “small” wind turbine systems should have, and now have been, applied for intermediate and large wind turbines as well. An informational note was added below the scope of Article 694 (see 694.1) alerting the user of the Code that wind electrical systems can be interactive with other power productions sources or might be a stand-alone system. Wind electric systems can have ac or dc output, with or without electrical energy storage, such as batteries. Two new figures were introduced entitled Figure 694.1(a) and 694.1(b). (See Figure 1)

Figure 1: Reproduction of Figures 694.1(a) and 694.1(b) from 2014 NEC

Figure 1: Reproduction of Figures 694.1(a) and 694.1(b) from 2014 NEC

The product standards for wind turbines, UL 6141, Wind Turbine Converters and Interconnection Systems Equipment and UL 6142, Small Wind Turbine Systems both draw the same conclusion in that there is no need to draw a distinction between small, intermediate, and large wind electric systems. It was quickly recognized that the rules for the larger wind turbines did not exist in Article 694 in the 2011 NEC due to the limitation of the scope of the article to 100 kW or less. By making these simple changes outlined above, this made Article 694 applicable to all types of wind electric systems.

A Review of Article 694- 2017 NEC

This will in no way be an entire review of Article 694 as this information is available for your reading pleasure with the NEC. I will hit a few of what I consider the high points for this article. When looking for information in the NEC, one of the first places to go is the scope of an article. The scope of Article 694 tells the user of the Code that this article applies to wind (turbine) electric systems that consist of one or more wind electric generators and their related alternators, generators, inverters, controllers, and associated equipment. This is an important step so that you are able to determine what this article applies to before you begin installing or enforcing the requirements towards a project.

Definitions are located in Article 100 and the .2 sections of many chapter in the NEC. Many Code cycles ago, the NEC correlating committee took steps to make the Code more user friendly. One of these ways was making the .2 sections of articles that contain definitions the holding spot for the definitions pertaining to that article. This brought consistency to the NEC as a whole and allowed the user of the Code to quickly find a definition within a particular article. Section 694.2 contains eleven definitions pertaining to wind electric systems. See 694.2 for these definitions.

The installation of wind electric systems shall be installed only by qualified persons. (see NEC 694.7) The term “qualified person” is a defined term located in Article 100. A qualified person is defined as “one who has skills and knowledge related to the construction and operation of the electrical equipment and installations and has received safety training to recognize and avoid the hazards involved.” This definition is under the purview of National Fire Protection Association (NFPA) Code Making Panel-1 and is referenced throughout the NEC.

Listing and labeling requirements are very important to the safety of electrical installations. This is no different for wind electric systems and listing requirements can be found in 694.7(B). This section states that equipment “shall be listed and labeled or field labeled for the application.” This section goes on to say that “wind electric systems undergoing evaluation for this type of certification and listing shall be permitted to be operated in a controlled location with access limited to qualified personnel.” An informational note following 694.7(B) tells the user of the Code information about the use of testing for certification and listing. This is typically performed under the supervision of a qualified electrical testing organization. A list of these organizations can be found on the OSHA website.

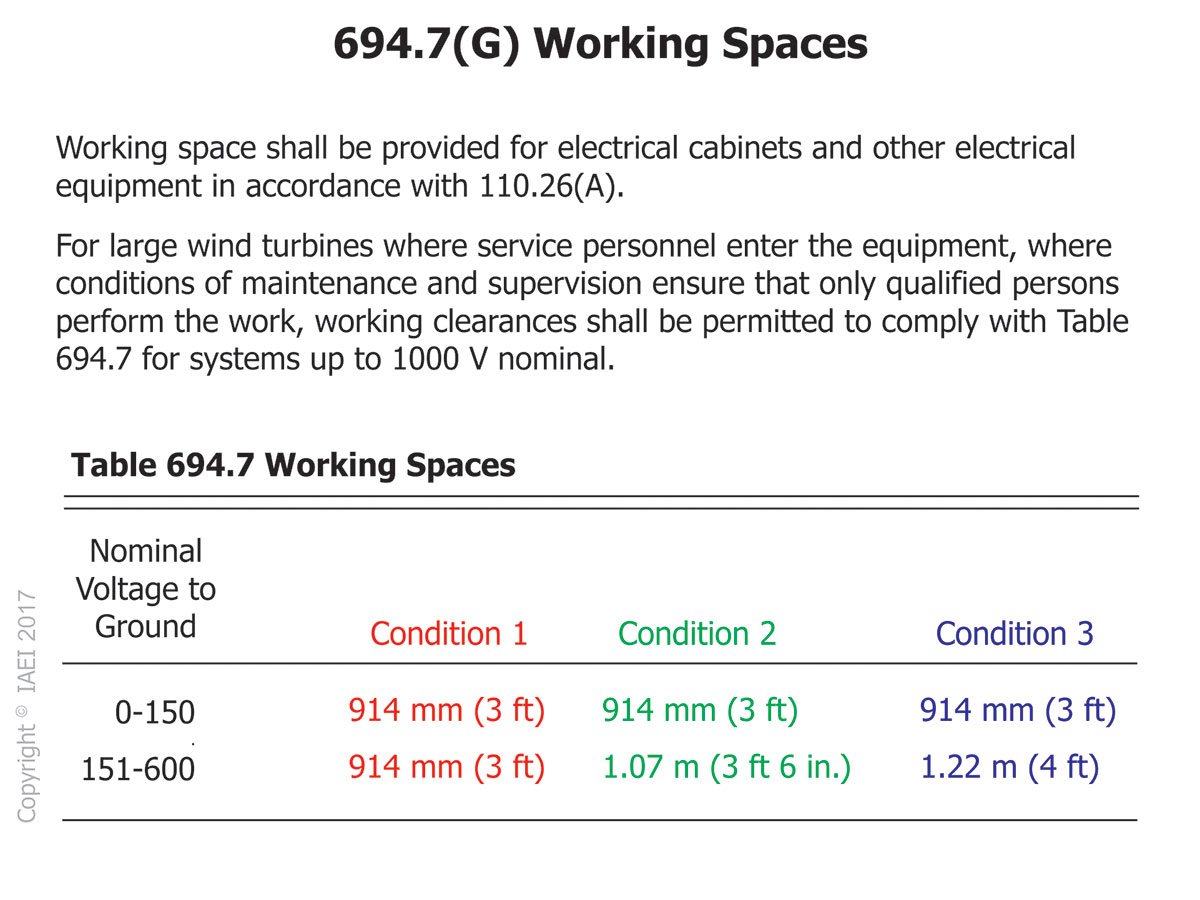

Another important concern regarding worker safety is the availability of working space. This is addressed in 694.7(G) and states that it shall be provided for electrical cabinets and other electrical equipment in accordance with 110.26(A). Section 110.26 is entitled Spaces About Electrical Equipment with (A) entitled Working Space. The Code further states that for large wind turbines where service personnel enter the equipment, where conditions of maintenance and supervision ensure that only qualified persons perform the work, working clearances shall be permitted to comply with Table 694.7 for systems up to 1000 V nominal. (See Photo 2)

Table 694.7 is similar to Table 110.26(A)(1) and includes voltages and conditions that determine the working space. (See Figure 2)

Figure 2: Table 694.7 for working spaces.

Figure 2: Table 694.7 for working spaces.

Interestingly, Table 694.7 does not contain notes that explain the different conditions types of 1,2, or 3 as it is found in Table 110.26(A)(1). This may be an opportunity for a public input for the 2023 NEC code cycle, but my guess is that the conditions as explained at Table 110.26(A)(1) will be the same for Table 694.7. These conditions are as follows:

- Condition 1 — Exposed live parts on one side of the working space and no live or grounded parts on the other side of the working space, or exposed live parts on both sides of the working space that are effectively guarded by insulating materials.

- Condition 2 — Exposed live parts on one side of the working space and grounded parts on the other side of the working space. Concrete, brick, or tile walls shall be considered as grounded.

- Condition 3 — Exposed live parts on both sides of the working space.

Overcurrent protection is always a concern and is discussed in detail 694.15. For circuits and equipment, such as turbine output circuits, inverter output circuits, and storage battery circuit conductors, these items are required to be protected in accordance with the requirements of Article 240 which is entitled Overcurrent Protection. Circuits connected to more than one electrical source shall have overcurrent devices located that will provide overcurrent protection from all the individual sources.

Requirements for disconnecting means for all conductors associated with a wind-electric system can be found at 694.20. This section states that a means shall be provided to disconnect all current-carrying conductors of a wind electric power source from all other conductors in a building or other structure. This section furthermore states that a switch, circuit breaker, or other device, either ac or dc, shall not be installed in a grounded conductor if operation of that switch, circuit breaker, or other device leaves the marked, grounded conductor in an ungrounded and energized state.

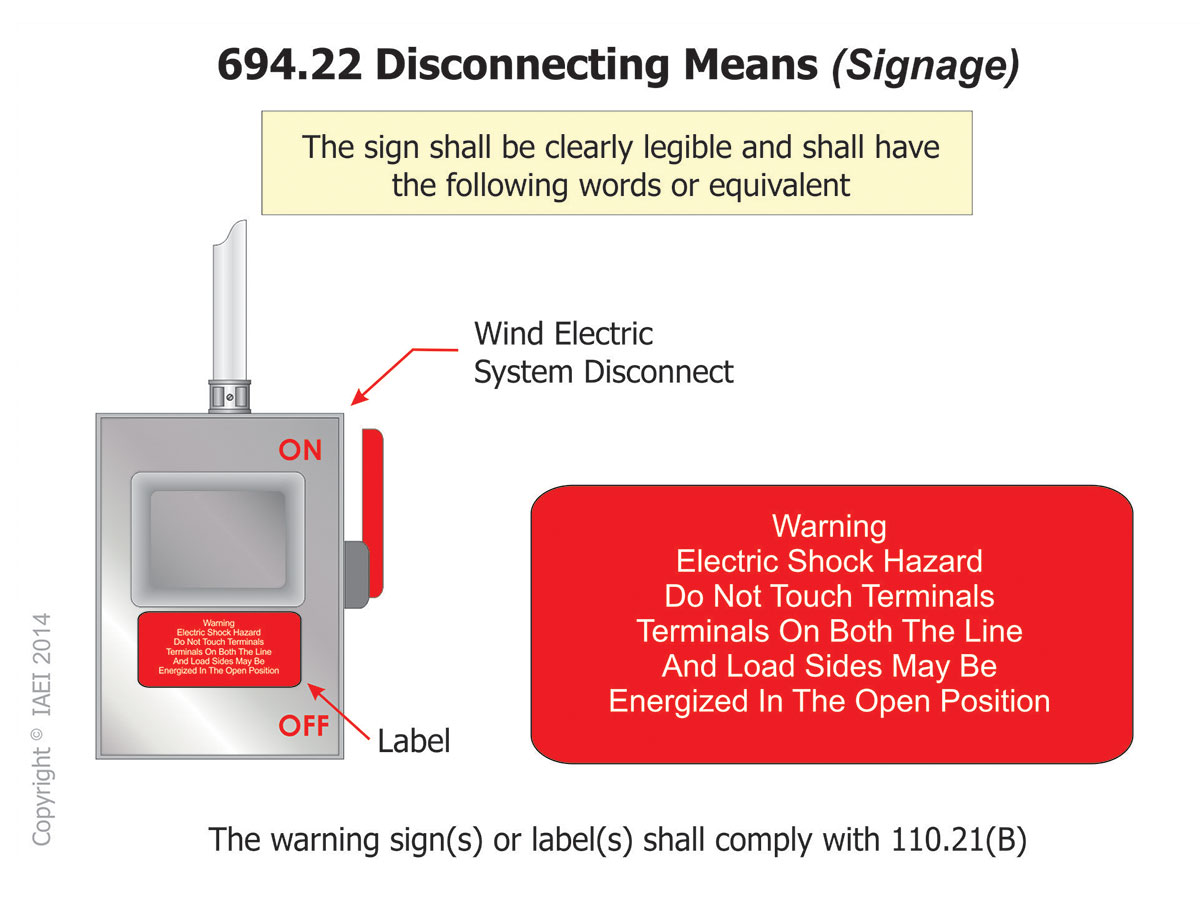

Figure 3: Figure shows the label text requirements for disconnects that may be energized in the open position for wind electric production products.

Figure 3: Figure shows the label text requirements for disconnects that may be energized in the open position for wind electric production products.

Where all terminals of the disconnecting means are capable of being energized in the open position, a warning sign shall be mounted on or adjacent to the disconnecting means. [see NEC 694.22(A)] The sign shall be clearly legible and shall have the following words or equivalent: (See Figure 3)

WARNING.

ELECTRIC SHOCK HAZARD.

DO NOT TOUCH TERMINALS.

TERMINALS ON BOTH THE LINE

AND LOAD SIDES MAY BE

ENERGIZED IN THE OPEN POSITION.

The warning sign(s) or label(s) shall comply with 110.21(B). The information found at 110.21(B) give the user of the Code requirements where caution, warning, or danger signs or labels are required. This information removed a lot of redundant text throughout the NEC when it came to field-applied hazard marking. The marking shall warn of the hazards using effective words, colors, symbols, or any combination thereof. The label shall be permanently affixed to the equipment or wiring method and shall not be handwritten [see exception to 110.21(B)]. In addition, the label shall be of sufficient durability to withstand the environment involved. See ANSI Z535.4-2011, Product Safety Signs and Labels, provides guidelines for the design and durability of safety signs and labels for application to electrical equipment.

There are provisions that give direction to personnel towards the shutdown procedures for a wind turbine. This is important as instances can arise where turbine runaway can result in a fire or destruction of the wind tower turbine.

This important information is found at 694.23 entitled Turbine Shutdown. Part (A) of 694.23 discusses manual shutdown of a wind turbine and states it shall be required to have a readily accessible manual shutdown button or switch. Operation of the button or switch is required to result in a parked turbine state that shall either stop the turbine rotor or allow limited rotor speed combined with a means to de-energize the turbine output circuit. [see exception to 694.23(A)] The shutdown procedure for a wind turbine is required to be defined and permanently posted at the location of a shutdown means and at the location of the turbine controller or disconnect, if the location is different. [see NEC 694.23(B)]

The types of wiring methods allowed for wind electric systems can be found at 694.30. This section states that all raceway and cable wiring methods included in this Code, and other wiring systems and fittings specifically intended for use on wind turbines, shall be permitted when identified for the application involved. The Code further states that in readily accessible locations, turbine output circuits that operate at voltages greater than 30 volts shall be installed in raceways.

Another very important safety concern is the proper installation requirements concerning grounding and bonding. In general, exposed non–current-carrying metal parts of towers, turbine nacelles, other equipment, and conductor enclosures shall be grounded and bonded to the premises grounding and bonding system. Attached metal parts, such as turbine blades and tails that are not likely to become energized, shall not be required to be grounded or bonded. [see NEC 694.40(A)]

In List Item (B) of 694.40 for tower grounding and bonding, the Code states that a wind turbine tower shall be connected to a grounding electrode system. See 250.52(A) of the NEC for items that qualify as part of the grounding electrode system. It is possible that a concrete-encased electrode exists as part of the foundation of the wind tower shown in the photo and qualifies as a grounding electrode. (See Photo 3)

Photo 3: Wind tower base showing a connection to a ground rod. Note: check the construction of the foundation as this may also qualify as a grounding electrode.

Photo 3: Wind tower base showing a connection to a ground rod. Note: check the construction of the foundation as this may also qualify as a grounding electrode.

Marking requirements are critical to safety and the availability of proper information for the life of these systems. Section 694.50 and 694.52 contain important information to help all person involved in the maintenance of these systems. All interactive system points of interconnection with other sources shall be marked at an accessible location at the disconnecting means and with the rated ac output current and the nominal operating ac voltage. (see NEC 690.50) It is very important to consider the environment where these marking will be installed. The sun, rain, sleet and ever-changing temperature conditions will take a readable marking of today to a non-readable marking in a few years. If this system will remain operational for 20-25 years, the marking system should be legible for that long. Consider the use of labels that are rated for sunlight and UV exposure. Think about the adhesive used to attach the labels. If water accumulates behind the label and freezes, this could result in the label falling off the equipment. In some cases, a rivet attachment may prove more dependable than other attachment means.

The availability of energy storage systems is in high demand as customers look for ways to store overproductions of alternative energies from their wind or photovoltaic (PV) systems. There may be cases where used electric vehicle (EV) batteries find new uses as energy storage for businesses and other locations. When an EV battery is no longer efficient for vehicle use, they are being used for energy storage needs. With this in mind, it is important that wind electric systems employing energy storage be marked with the maximum operating voltage, any equalization voltage, and the polarity of the grounded circuit conductor.

If you happen to live in a part of this great country where any direction you go means you are coming out, you may not have access to an electric utility provider for your electricity needs. In this case, you may need to rely upon a wind-electric system or other form of alternative energy for your electricity needs. This type of system would be deemed a stand-alone system. The buildings or structures served by this type of system shall have special marking requirements. When they are provided with a stand-alone system (such as a wind electric production system) and not connected to a utility service source, the building or structure is required to have a permanent plaque or directory installed on the exterior at a readily visible location. The plaque or directory shall indicate the location of system disconnecting means and shall indicate that the structure contains a stand-alone electrical power system.

And finally, when the wind energy system will be interacting with other electrical sources (utility, PV, etc.), there is a need that this equipment be listed, labeled, and identified as interactive with the various systems. Wind electric systems, where connected to utility electric sources, are required to comply with the requirements of Article 705, Interconnected Electric Power Production. The points of connections to interconnected electric power sources shall comply with 705.12 entitled Point of Connection.

At Journeys End

I hope that you enjoyed our trip back into time and the exploration of how wind electric production systems became a part of the NEC. I was involved with an installation of this nature many years ago and the edition of the NEC enforced within the jurisdiction was silent on what needed to be done. I leaned on the manufactures instructions and a lot of research into the system. I was even able to utilize industry experts I had met during IAEI functions for assistance. In the end, I feel that we did the best we could do to assure the installation was compliant and safe.

Sometimes it takes a while for the industry to see the need to address a particular topic in the NEC. It is ultimately the responsibility of every user of the Code to review and maintain this document so that it is relevant and continues to keep you and your families electrically safe.

Find Us on Socials